The Beauty of the Invisible: Unterschied zwischen den Versionen

Keine Bearbeitungszusammenfassung |

Keine Bearbeitungszusammenfassung |

||

| Zeile 43: | Zeile 43: | ||

The contours of all framework components are given a matt finish to create a vivid interplay with the polished edges. | The contours of all framework components are given a matt finish to create a vivid interplay with the polished edges. | ||

<br style="clear:both;" /> | <br style="clear:both;" /> | ||

[[Datei:Schwarzpolitur.jpg|thumb| | [[Datei:Schwarzpolitur.jpg|thumb|Black polish]] | ||

=== | === The black polish === | ||

Black polish – the most sophisticated and challenging finishing technique – is performed exclusively on the tourbillon bridge and cage. It can take up to five days to polish one single part. | |||

<br style="clear:both;" /> | <br style="clear:both;" /> | ||

[[Datei:Gravur.jpg|thumb|Gravur]] | [[Datei:Gravur.jpg|thumb|Gravur]] | ||

Version vom 4. August 2011, 01:43 Uhr

The Beauty of the Invisible

Traditional finish techniques at A. Lange & Söhne

A. Lange & Söhne timepieces of the 21st century constitute the link to a heritage that began in Saxony more than 165 years ago. From the very beginning, Ferdinand A. Lange described his business philosophy as follows: “With the knowledge that quality craftsmanship always assures the most advantageous purchase, we are aware that we can render the best service to our clientele by supplying only watches of the highest class.” Lange still upholds this commitment to the ethics of the artisan, because this alone creates a little piece of eternity in an ever changing world.

Indeed, A. Lange & Söhne timepieces still feature quality hallmarks that were once the norm in high-end watchmaking, but which were gradually abandoned in favour of costeffectiveness in production. Among the typical hallmarks are the surface finishes applied to nearly all movement parts. For the owner of such a piece of art, the composition of aesthetic details is matched by the mechanical precision of the movement. Every single one of them illustrates the manufactory’s uncompromising quest for perfection.

Here is an overview of the most important finish techniques:

The sunray finish

The sunray finish is mainly used on bigger wheels and parts of the framework. The graining results in a spirally pattern.

The Glashütte ribbing

The Glashütte ribbing emulates a gently rippled effect. The pattern decorates the three-quarter plate and some other large parts of the framework.

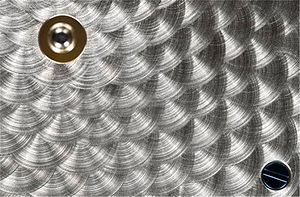

The circular graining

Circular graining is used on round shapes such as wheels. Unlike most other finishes, this one is applied by rotating the part around the tool.

The linear finish

The fine lines in a parallel direction are achieved by sliding a part in one direction over a piece of abrasive paper.

The perlage

The perlage consists of small, overlapping circles, achieved with a rotating grinding tip. In A. Lange & Söhne watches, it is mainly used for bridges and plates.

The flat polish

The mirror-smooth surface of the flat polish is achieved by rubbing the part in a figure-eight motion on special foils coated with diamond dust.

Chamfering

At Lange every single bevel on almost all

parts is polished by hand, at an angle of exactly 45 degrees. Sharp inner corners are particularly challenging.

Contour grinding

The contours of all framework components are given a matt finish to create a vivid interplay with the polished edges.

The black polish

Black polish – the most sophisticated and challenging finishing technique – is performed exclusively on the tourbillon bridge and cage. It can take up to five days to polish one single part.

Die Gravur

Die Gravur lässt jeden Zeitmesser von A. Lange & Söhne zum Unikat werden: Jeder Unruhkloben wird von einem von sechs Meistergraveuren im freien Schnitt mit einem floralen Muster verziert.