The genesis of a masterpiece: Unterschied zwischen den Versionen

Keine Bearbeitungszusammenfassung |

Keine Bearbeitungszusammenfassung |

||

| Zeile 7: | Zeile 7: | ||

The GRAND COMPLICATION is a homage to the grand tradition of Saxon precision watchmaking and also marks the dawn of a new era in the history of A. Lange & Söhne. According to Lange’s Product Development Director Anthony de Haas, the development of this complication and its fascinating chiming mechanism “unleashed creative momentum among our product designers and opened up a wide passageway for new solutions.” | The GRAND COMPLICATION is a homage to the grand tradition of Saxon precision watchmaking and also marks the dawn of a new era in the history of A. Lange & Söhne. According to Lange’s Product Development Director Anthony de Haas, the development of this complication and its fascinating chiming mechanism “unleashed creative momentum among our product designers and opened up a wide passageway for new solutions.” | ||

The GRAND COMPLICATION incorporates a grand and small strike, a minute repeater, a split-seconds chronograph with a minute counter and flying seconds, as well as a perpetual calendar with a moon-phase display. Only the most talented and experienced watchmakers have the skills needed to master the challenges associated with the assembly and intricate adjustment of the 876-part movement. And even they need a whole year to get the job done. The task requires in-depth expertise, concentration, dexterity, and – above all – patience. | The GRAND COMPLICATION incorporates a grand and small strike, a minute repeater, a split-seconds chronograph with a minute counter and flying seconds, as well as a perpetual calendar with a moon-phase display. Only the most talented and experienced watchmakers have the skills needed to master the challenges associated with the assembly and intricate adjustment of the 876-part movement. And even they need a whole year to get the job done. The task requires in-depth expertise, concentration, dexterity, and – above all – patience. | ||

This is because the assembly process also includes exhaustive tests, especially to ensure correct functioning of the chiming mechanism. For this purpose, the strikes are recorded in 24-hour cycles over a period of several weeks. The subsequent evaluation of the recordings is performed to confirm that the mechanism properly sounds all quarter hours. If this is not the case, it must be completely disassembled, readjusted, reassembled and tested again. “Free without play”: This is the – actually physically impossible – instruction passed on to the watchmaker as a description of the ideal interaction of the moving parts of a chiming mechanism. | |||

[[de:Die Entstehung eines Meisterwerks]] | [[de:Die Entstehung eines Meisterwerks]] | ||

[[en:The genesis of a masterpiece]] | [[en:The genesis of a masterpiece]] | ||

Version vom 9. Juni 2016, 23:08 Uhr

A. Lange & Söhne delivers the first GRAND COMPLICATION

Glashütte, June 2016

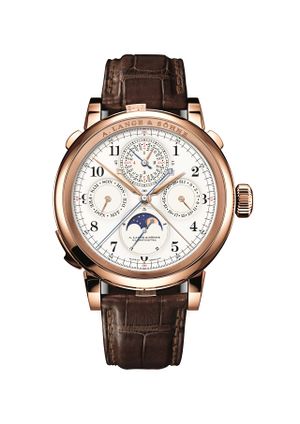

In January 2013, A. Lange & Söhne presented the most complicated wristwatch ever built in Germany. Only six of these oeuvres will ever be crafted, and the first one has now been handed over to its owner. The assembly of the movement alone requires an entire year for each watch. Meanwhile, some of the countless steps involved in the making of this micromechanical masterpiece have been photographically documented.

The GRAND COMPLICATION is a homage to the grand tradition of Saxon precision watchmaking and also marks the dawn of a new era in the history of A. Lange & Söhne. According to Lange’s Product Development Director Anthony de Haas, the development of this complication and its fascinating chiming mechanism “unleashed creative momentum among our product designers and opened up a wide passageway for new solutions.”

The GRAND COMPLICATION incorporates a grand and small strike, a minute repeater, a split-seconds chronograph with a minute counter and flying seconds, as well as a perpetual calendar with a moon-phase display. Only the most talented and experienced watchmakers have the skills needed to master the challenges associated with the assembly and intricate adjustment of the 876-part movement. And even they need a whole year to get the job done. The task requires in-depth expertise, concentration, dexterity, and – above all – patience.

This is because the assembly process also includes exhaustive tests, especially to ensure correct functioning of the chiming mechanism. For this purpose, the strikes are recorded in 24-hour cycles over a period of several weeks. The subsequent evaluation of the recordings is performed to confirm that the mechanism properly sounds all quarter hours. If this is not the case, it must be completely disassembled, readjusted, reassembled and tested again. “Free without play”: This is the – actually physically impossible – instruction passed on to the watchmaker as a description of the ideal interaction of the moving parts of a chiming mechanism.