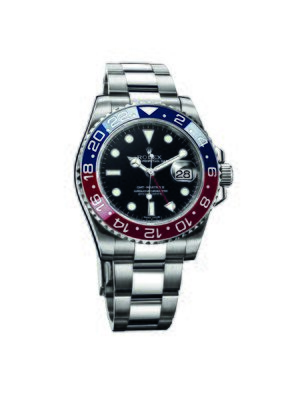

Rolex Oyster Perpetual GMT-Master II with two-colour Cerachrom bezel

| MANUFACTURING PROCESS Rolex’s total in-house mastery of the whole process of manufacturing ceramic components made the creation of the two-colour Cerachrom bezel possible – along with a good measure of ingenuity to find technical solutions to hurdles once regarded as impossible to overcome. Two patents were filed on this exclusive Rolex process. Injection moulding Impregnation Sintering Precision machining Graduations Polishing |

Baselworld 2014

Brochure

Basel, 26 March 2014

HOW ROLEX ACHIEVED THE IMPOSSIBLE

THE MYTHICAL RED AND BLUE CERECHROM BEZEL INSERT

Some things do not exist for a very simple reason: they are considered impossible to create. That is what was said about two-colour ceramic. No one had managed to discover a way of manufacturing a watch component in high-technology ceramic with bulk colouring in two distinct colours. No one before Rolex...

A WORLD FIRST

The Cerachrom bezel insert in blue and black introduced by Rolex in 2013 was a world first. It was made in a single piece and the clear-cut demarcation of colours on each half of the insert was perfectly executed. This year, Rolex has pushed the technical and aesthetic prowess yet further on its Oyster Perpetual GMT-Master II, unveiling a red and blue Cerachrom bezel insert, echoing the first GMT-Master bezel of 1955. An exceptional achievement on two counts: firstly, red is an extremely difficult colour to obtain and, therefore, an unusual colour for ceramic; secondly, having succeeded in creating a red insert, Rolex then found a way to locally modify the chemical composition of each grain, right to the core of the ceramic, and change the colour of half the insert from red to blue, while ensuring a sharp delineation between the two colours.

HIGH TECHNOLOGY AND ICONIC AESTHETICS

The resulting bulk-coloured, single-piece Cerachrom insert is red for the hours between 6 a.m. and 6 p.m. and blue for the hours between 6 p.m. and 6 a.m. By virtue of being manufactured in a single piece, the insert acquires mechanical resistance properties that respond to the quality and reliability demanded of a Rolex product. Like all Rolex Cerachrom bezel inserts, it offers exceptional scratch and corrosion resistance. Its colours are unaffected by ultraviolet rays. The aesthetic effect is equally spectacular. The ceramic’s sheen gives volume to the insert and enhances the colours in a way that is reminiscent of the Plexiglas insert of the original GMT-Master. The engraved numerals and graduations are coated with a thin layer of platinum via a PVD (Physical Vapour Deposition) process patented by Rolex. Their depth and matt finish underscore the contrast with the insert’s polished surface, producing a three-dimensional effect that ensures optimal legibility.

PUSHING THE BOUNDARIES OF THE POSSIBLE

The new GMT-Master II’s two-colour red and blue Cerachrom insert is a unique, high-technology ceramic component, which adds new patents to the Cerachrom insert developed by Rolex in 2005. It combines the exceptional technical performance of the Cerachrom bezel with the GMT-Master’s iconic two-colour appearance. And it perpetuates the Rolex tradition of constantly extending the boundaries of the possible.

Red is an extremely difficult colour to obtain and,

therefore, an unusual colour for ceramic.

IN THE BEGINNING, THERE WAS RED AND BLUE

From its launch in 1955, the Rolex GMT-Master stood out with its rotatable 24-hour graduated red and blue bezel. Thanks to an additional hand that circled the dial once every 24 hours, airline pilots on intercontinental flights – a rapidly expanding sector at the time – could read the time in two time zones simultaneously. Red and blue, situated at opposite ends of the colour spectrum, are strongly contrasting colours for the human eye, a determining factor for legibility on a Professional watch. The first GMT-Master bezel inserts were made of transparent Plexiglas, painted half red and half blue on the underside. This method of production gave a certain depth to the bezel, as the colour showed through the Plexiglas.

In 1959, still in the original two colours, the Plexiglas insert was replaced by one in anodized aluminium once the manufacture of a two-colour insert in this material had been mastered. Various other combinations were introduced later, such as brown and gold on Rolesor (steel and gold) models, or burgundy and black on the GMT-Master II launched in 1982. But in the minds of many GMT-Master lovers, a red and blue bezel remains the signature feature of this model.

THE CERACHROM BEZEL, AN IDEAL CERAMIC COMPONENT

In 2005, after several years’ research, Rolex developed in-house and patented a new high-performance component to equip the rotatable bezels of its watches: the Cerachrom insert. The polished surface of this extremely resistant ceramic insert features a deep, long-lasting lustre and provides a sharp contrast to the precisely engraved numerals and graduations coated in a thin layer of gold or platinum. Ceramic is a material with exceptional robustness and durability: it is virtually scratchproof, resistant to corrosion, and its colour is unaffected by ultraviolet rays. For Rolex, a brand that constantly seeks to innovate and perfect, this material constitutes the ideal replacement for the previously used anodized aluminium. The Oyster Perpetual GMT-Master II was the first model in the Oyster collection to benefit from the Cerachrom bezel technology, and the new Cerachrom insert was adopted in 2005 in a uniform black colour.

ROLEX KNOW-HOW

In keeping with its quality standards and its mastery of the production of all its key watch components, Rolex developed in-house the expertise, processes and high-technology equipment needed to acquire complete independence in the production of its ceramic components. The workshops are housed at the impressive Rolex Plan-les-Ouates production site on the outskirts of Geneva. There, the brand makes all the elements for its cases and bracelets, starting with the casting of its own gold alloys or the sourcing of other raw materials, to their machining, assembly and polishing. The production of ceramic components is completely mastered, from raw material to the finished Cerachrom bezel insert. Such complete in-house mastery allows Rolex to devise innovative solutions and create components that correspond exactly to its specifications and quality criteria. Since 2007, Rolex expertise has produced exclusive Cerachrom bezel inserts in blue and in green – in addition to black – for its Oyster Perpetual Submariner Date models or its 18 ct yellow gold Oyster Perpetual Yacht-Master II. In 2010, it took another leap forward in developing a monobloc Cerachrom bezel – rather than a bezel insert – to equip the Cosmograph Daytona. It first appeared in black, and then in brown in 2013 on the platinum version that marked the 50th anniversary of the legendary chronograph.

During all this time, the creation of a two-colour ceramic bezel – which should, moreover, be half red – remained mission impossible from a technical point of view. Yet the extensive internal resources of the Research and Development Department took up the challenge and finally managed to combine the technical performance of the Cerachrom bezel with the iconic two-colour aesthetics of the GMT-Master. In 2013, after many years of research and fine-tuning the exclusive manufacturing process, Rolex unveiled the first two-colour Cerachrom insert in the world – in blue and black. Now, in 2014, that mission has been brought to a successful conclusion with the introduction of a two-colour Cerachrom insert in red and blue that complies with Rolex’s strict quality standards for its watch components.

Rolex developed in-house the expertise,

processes and high-technology equipment needed.

RED AND BLUE CERACHROM

The name “Cerachrom” derives from a contraction of the word “ceramic” juxtaposed with the suffix “chrom” from the ancient Greek word for “colour”. The range of available shades for ceramic is however restricted by its very manufacturing process. Colours are generally created by adding mineral pigments that can withstand the very high temperatures at which the ceramic is fired for its densification and to acquire its characteristic hardness. Red, typically, is a colour for which no stable mineral pigments exist to create a Cerachrom component. Rolex nevertheless managed, in the first instance, to produce a red ceramic according to a secret process. But, for the brand, this innovation represented only half the journey – or, more precisely, took the brand only half way to manufacturing the emblematic red and blue Cerachrom insert.

Rolex’s in-house engineers finally found an answer to the second half of the challenge. The ingenious process consists of introducing an intermediate step in the manufacture of the standard Cerachrom insert. During this innovative bulkcolouring step, half of the red ceramic insert is coloured blue. The colour is achieved by impregnating the part of the insert representing night-time hours, between 6 p.m. and 6 a.m., with a controlled quantity of a solution of chemical compounds. The solution is added before sintering at more than 1,600 °C, when the ceramic acquires its mechanical resistance properties as well as its colour. In the course of this firing, the ceramic densifies and the added compounds react with the basic elements of the red Cerachrom insert to conjure up the final blue colour.

Although the idea in itself may appear simple, a number of major technical hurdles had to be overcome before it could be implemented: the formulation of a solution of precursor chemical compounds that would turn red into blue; the homogenous application of an appropriate quantity of this solution; ensuring a sharp, precise and clear demarcation between the two coloured areas, the definition of the precise length of time and temperature for the sintering so as to prevent any distortion of the piece. Every single one of these parameters is crucial for the success of the process and the quality of the final product.

PIONEERING TRADITIONS

Pushing back the boundaries of the possible is a strong tradition at Rolex. In the early 20th century, when the highest precision could be achieved only by large marine chronometers, Rolex obtained, in 1914, the first “Class A” certificate for chronometric precision ever granted to a wristwatch by the prestigious Kew Observatory. Although at the time the idea of a waterproof and dustproof watch was totally inconceivable, Rolex created the Oyster in 1926, the first waterproof wristwatch in the world, and displayed it in shop windows in a goldfish bowl filled with water. Since then, Rolex has registered more than 400 patents and continues to innovate in all fields of watchmaking, setting, over the years, the standards for watches today.

THE OYSTER PERPETUAL GMT-MASTER II

The traveller’s watch

The Oyster Perpetual GMT-Master II is renowned as the watch for long-haul travellers. Precise, reliable and functional, it was designed to allow airline pilots to read the time in two different time zones simultaneously. The new-generation GMT-Master II with two-colour Cerachrom bezel inserts in ceramic is a distillation of Rolex expertise and technology that remains faithful to the style of the legendary watch created in 1955.

Greenwich Mean Time

In function as well as in name, the GMT-Master II evokes intercontinental travel across time zones. Greenwich Mean Time (GMT) marks mean solar time at the Royal Observatory in Greenwich, London − the location of the original meridian used for calculating longitude and determining different time zones around the world.

As intercontinental travel developed in the 1950s with the advent of the jet age, airliners began to fly swiftly across several successive time zones, making it important to know simultaneously the time in various places in the world (such as the airport of departure and arrival, or local time and GMT reference time). The GMT-Master was developed to meet the specific needs of airline pilots. It became the official watch of the famous Pan American World Airways, better known as Pan Am.

Two time zones simultaneously

An evolution of the first model, the GMT-Master II was launched in 1982. In addition to conventional hour, minute and seconds hands, it features an arrow-tipped hand which circles the dial once every 24 hours as well as a bidirectional rotatable 24-hour graduated bezel. This 24-hour hand displays the reference time in a first time zone (‘home’ time for example), which can be read on the graduations on the bezel.

Travellers can read local time on the dial, indicated by the hour hand. It is easily set when crossing time zones, by “jumping” from hour to hour thanks to an ingenious mechanism operated via the winding crown. The adjustment can be made independently of the minute and seconds hands, without affecting the time for the first time zone or stopping the watch. As a result, travellers can simultaneously read the time where they are as well as their reference time, which is displayed in a 24-hour format to clearly differentiate daytime hours from night-time hours (for example 10 a.m. and 10 p.m.).

If desired, the time in a third time zone can also be displayed by turning the graduated bezel the corresponding number of hours. The time in this zone is indicated by the 24-hour hand against the bezel.

Travellers can simultaneously read the time where they are

as well as their reference time.